TECHNOLOGY

The Hidden Shift Behind Novo’s Catalent Acquisition

Novo’s Catalent buyout spotlights a shift toward digital quality systems built to speed drug production without sacrificing compliance

21 Jan 2026

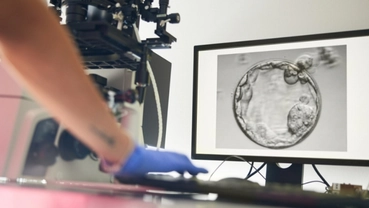

A gradual shift is taking place in US drug manufacturing as companies modernise how medicines are documented, reviewed and released, amid rising demand for complex and injectable therapies. Novo Holdings’ roughly $16.5bn acquisition of Catalent comes at a point when operational capability, rather than research alone, is drawing closer scrutiny.

The deal does not rest on a single technology choice. But it highlights a common pressure across the industry. Paper-based quality systems are struggling to keep pace with tighter timelines and more complex production. In regulated manufacturing, batch release depends on documentation reviews, deviation investigations and quality approvals. When records sit across binders, spreadsheets and disconnected systems, delays and compliance risks increase.

Catalent has been seeking to address these constraints through broader quality transformation efforts. These include adopting cloud-based document and information management tools to support more centralised and paperless workflows. The aim has been to improve visibility, reduce manual handovers and standardise processes across global sites, while meeting regulatory and cybersecurity requirements.

In public statements, Catalent has pointed to the role of secure digital platforms in managing regulated content and supporting clients as production volumes grow or shift between facilities. For customers, the benefits are operational rather than strategic. Quicker access to records, fewer transcription errors and smoother coordination between manufacturing and quality teams are among the practical gains.

Regulators have reinforced the importance of reliable recordkeeping, without mandating specific technologies. The US Food and Drug Administration has repeatedly warned that weak data controls can undermine product quality and slow approvals. Its guidance on data integrity stresses that records must be accurate, complete, secure and traceable, whether systems are paper-based or digital.

The transition is not without obstacles. Integrating newer platforms with legacy manufacturing and laboratory systems can be difficult, and cybersecurity risks require constant oversight. Organisational change also plays a role, as companies move staff away from paper-driven routines towards more automated processes.

Even so, the direction of travel is becoming clearer. Large transactions such as the Catalent acquisition are expected to sharpen competition among contract development and manufacturing organisations, with operational maturity increasingly a differentiator. As manufacturing grows more complex and timelines shorten, companies that modernise quality systems while maintaining compliance may be better placed for the next phase of drug production.

Latest News

2 Feb 2026

A $20M Bet That Brain Implants Can Fix Drug Failure30 Jan 2026

A Flash of Light, No Injection Required29 Jan 2026

Can FDA’s Softer Rules Spark a Cell Therapy Boom?27 Jan 2026

How a New Partnership Is Changing Complex Drug Design

Related News

INSIGHTS

2 Feb 2026

A $20M Bet That Brain Implants Can Fix Drug Failure

RESEARCH

30 Jan 2026

A Flash of Light, No Injection Required

REGULATORY

29 Jan 2026

Can FDA’s Softer Rules Spark a Cell Therapy Boom?

SUBSCRIBE FOR UPDATES

By submitting, you agree to receive email communications from the event organizers, including upcoming promotions and discounted tickets, news, and access to related events.