INNOVATION

How Advanced Manufacturing Is Reshaping US Pharma

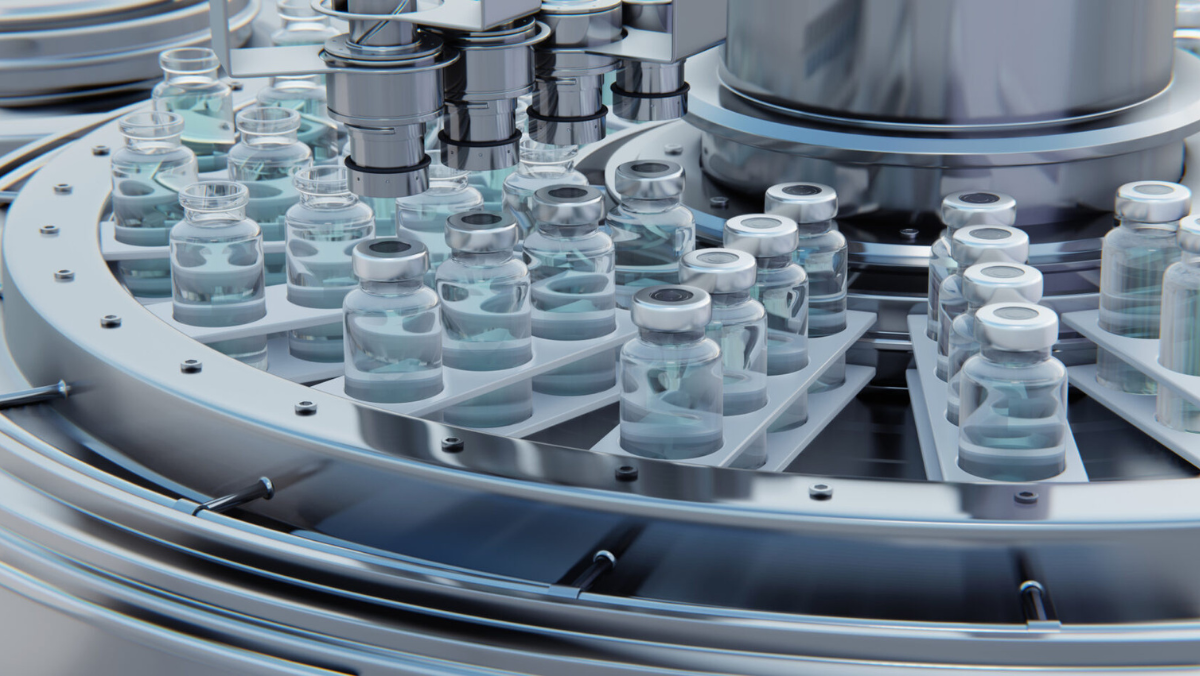

US drugmakers expand advanced manufacturing as supply risks and new FDA frameworks push modernization

12 Dec 2025

US pharmaceutical companies are accelerating investment in advanced manufacturing as they seek to secure supply chains, improve quality and prepare for a new generation of complex medicines.

The shift has been under way for several years but has gained visibility after a series of high-profile announcements, including Eli Lilly’s multibillion-dollar plan to build a new manufacturing facility in the US. The project reflects a broader industry effort to modernise domestic production using digital systems, real-time monitoring and more flexible, precision-based operations.

Drugmakers say repeated shortages and supply chain disruptions in recent years have exposed weaknesses in traditional manufacturing models. Those pressures have strengthened the case for resilient production capacity that can be scaled more quickly and monitored more closely.

Advanced facilities are designed to support therapies that require tighter quality control, including peptide-based treatments and some oral drugs. Small variations in temperature, timing or formulation can affect performance, making automation and continuous monitoring more important. Companies argue that digital systems can identify deviations earlier and maintain more consistent output.

The benefits extend beyond quality. Expanding domestic capacity reduces reliance on overseas suppliers and allows faster responses to shifts in demand. That flexibility is becoming more valuable as treatments for chronic diseases grow in volume and personalised medicines move closer to commercial scale.

Regulators are also encouraging the transition. The US Food and Drug Administration has introduced initiatives to support advanced manufacturing, including its FRAME programme, which promotes the use of new technologies to improve oversight and reduce shortages. The agency has said modernised facilities can streamline inspections and approvals while strengthening supply resilience.

The move is not without obstacles. Building and upgrading plants requires significant capital, and companies need staff with expertise in both manufacturing and digital operations. Smaller drugmakers may turn to partnerships or contract manufacturers to access advanced capabilities without bearing the full cost.

Even so, industry executives say the direction of travel is clear. Manufacturing is becoming a strategic priority rather than a back-end function, shaping how quickly and reliably new therapies reach patients across the US.

Latest News

13 Feb 2026

Core-Shell LNP Study Signals Promise, Not Proof12 Feb 2026

FDA Aligns Device Rules With Global Standard11 Feb 2026

Smart Microneedle Patches Reshape Drug Delivery10 Feb 2026

Integrated CDMO Alliance Targets Oral Drug Timelines

Related News

RESEARCH

13 Feb 2026

Core-Shell LNP Study Signals Promise, Not Proof

REGULATORY

12 Feb 2026

FDA Aligns Device Rules With Global Standard

INNOVATION

11 Feb 2026

Smart Microneedle Patches Reshape Drug Delivery

SUBSCRIBE FOR UPDATES

By submitting, you agree to receive email communications from the event organizers, including upcoming promotions and discounted tickets, news, and access to related events.